Providing a high-efficiency nitrogen generation system for safe cargo transportation and prevention of cargo contamination.

Contributing to low OPEX by providing high efficiency and long CMS lifespan

Providing the optimal solution for line purging of the gas supply system and cargo inerting

ALL PRODUCT

N2-GEN is a Marine Inert Gas (Nitrogen) Supply system.

N2-GEN provides specialized gas processing systems for ships and offshore installations.

As a reliable supplier of onboard nitrogen systems, we meet the comprehensive applications and technical requirements of inerting systems for LNG, chemical, and oil carriers, and others.

N2-GEN provides specialized gas processing systems for ships and offshore installations.

As a reliable supplier of onboard nitrogen systems, we meet the comprehensive applications and technical requirements of inerting systems for LNG, chemical, and oil carriers, and others.

Applications

N2-GEN is a continuous and trouble-free supply system of Nitrogen on board for the following applications:

Features

PSA (Pressure Swing Adsorption) type inert gas generator has the following features and advantages over other types.

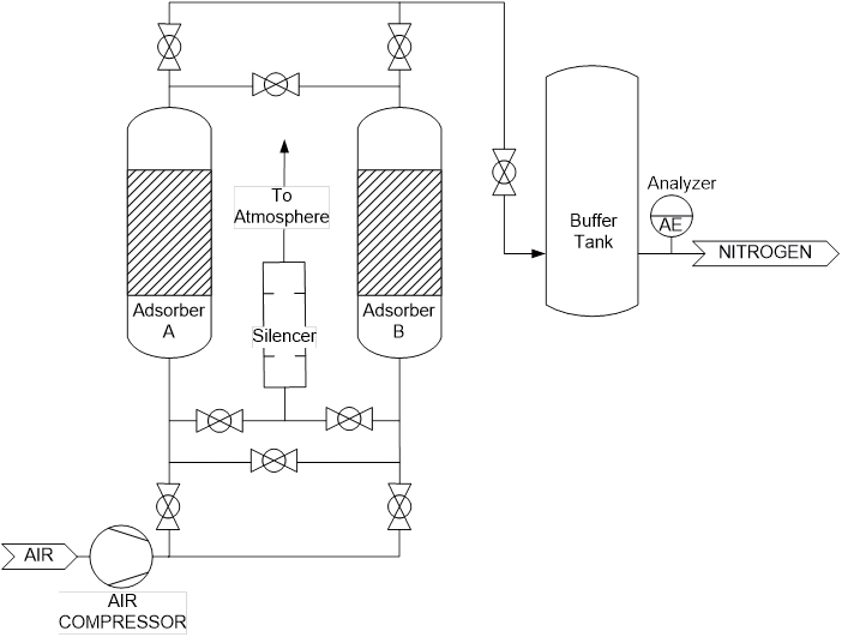

Working Principles

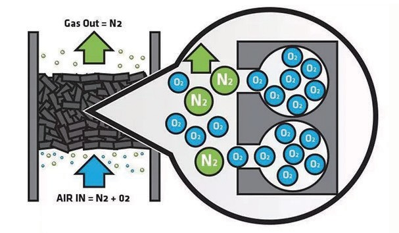

The operation of N2-GEN is based on the Pressure Swing Adsorption (PSA) principle, utilizing high-quality carbon molecular sieves as the adsorbent to separate nitrogen and oxygen.

The adsorbent adsorbs oxygen, carbon dioxide, and water vapor, while nitrogen passes through the adsorption layer and is separated.

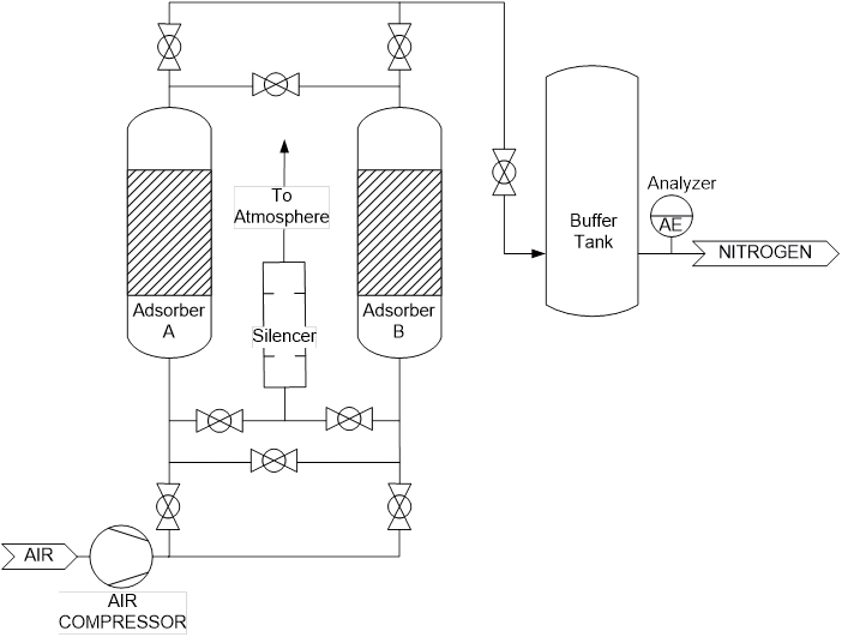

The system is composed of a service column and a standby column, which are periodically alternately regenerated to supply a continuous high-quality nitrogen.

Regeneration and service operations are automatically controlled, and the high-quality carbon molecular sieve provides long-term durability.

Carbon molecular sieve

Working of CMS

Operation of system

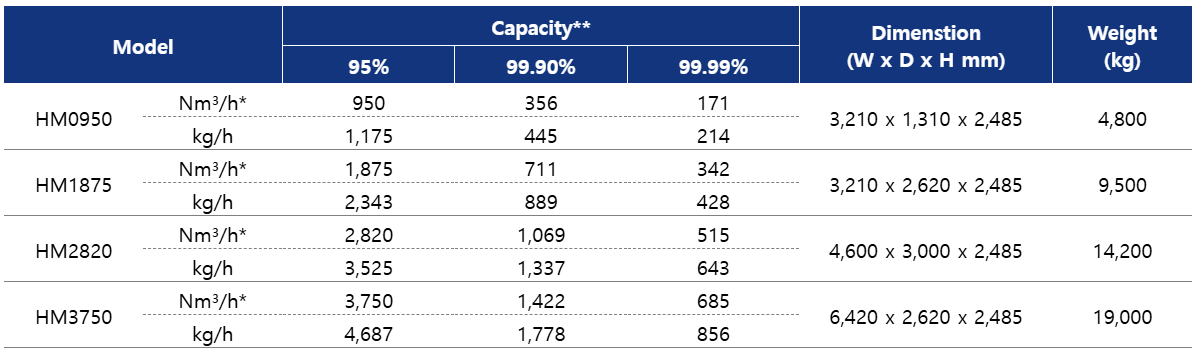

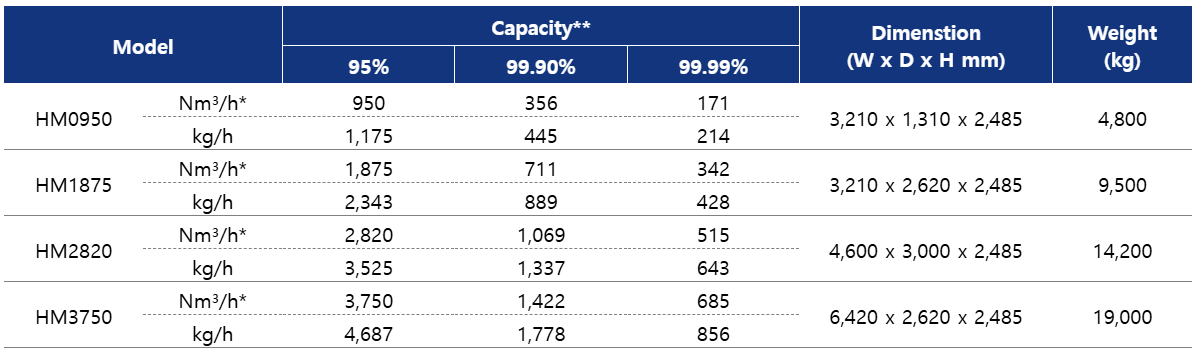

Line-up and Technical Specifications

*Volume flow rate [Nm³/h] is in the reference conditions (Temperature: 0°C, Pressure: 1.013 bar a).

**Capacities beyond those mentioned in the table can be supplied in customized capacities to meet customer requirements.

**Capacities beyond those mentioned in the table can be supplied in customized capacities to meet customer requirements.

Operating Conditions